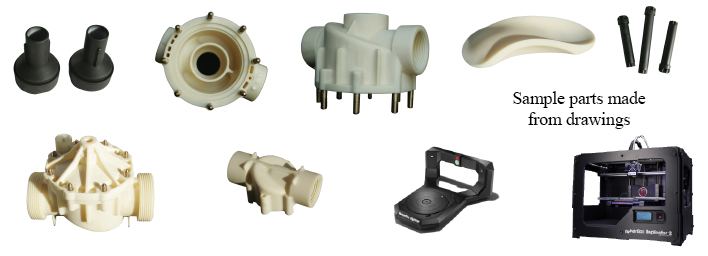

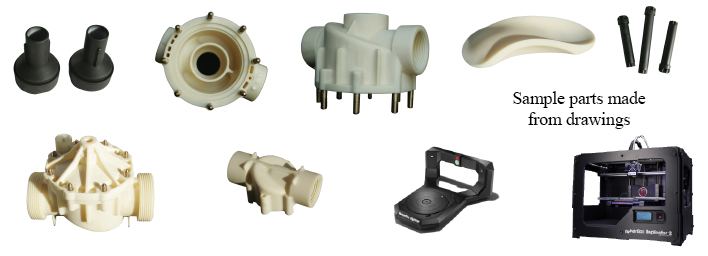

Servtech Plastics can convert 2D and 3D CAD-CAM drawings to physical parts by rapid prototyping, 3D printing and SLA models, creating conceptual models before tool production. The prototyping process builds strong and high detail samples from ABS plastic or composite materials. SLA models and prototypes are used to demonstrate and test product designs.

3-D Models / Prototypes

Part Validation

In order to reduces defect occurrences and ensure the highest product quality; we consistently validate parts from production, regardless of molding machine or manufacturing location. This technique ensures high quality standards, repeatable production, and consistent quality parts despite variation in molding materials and processing equipment. Our proven systematic approach involves rigorous statistical qualifications and custom development of mold-specific processes rather than machine specific leading to improved time to market and part quality.

The ISO-13485 standard specifically requires awareness and promotion of regulatory, inspection and traceability requirements for medical devices while also agreeing to document and validate the processes for medical devices.